Laagspanningsregelaar ACSR, IEC, BS, ASTM, DIN-standaard

Basic Info

CE ,

UL ,

CCC ,

RoHS

Extra Informatie.

Beschrijving

(1)Production capacity:5000 ton/month

(2)MOQ:1km

(3)Delivery:5~15 officail days.

(4)Standards:IEC,ASTM,DIN,BS; or according to customers’ requirements.

(5)Delivery length:as per customers’ request.

1,Bare Conductor Types

(1) all aluminum conductor (AAC)

(2) all aluminum alloy conductor(AAAC)

(3) aluminum conductor steel reinforced (ACSR)

(4) anti-corrosion type ACSR

(5) aluminum conductor aluminum clad steel reinforced(ACSR/AW)

(6) rear earth aluminum conductor steel reinforced(ACSR/RE)

(7) aluminum conductor aluminum alloy reinforced(ACAR)

(8)aluminium Conductor Steel Supported (ACSS)

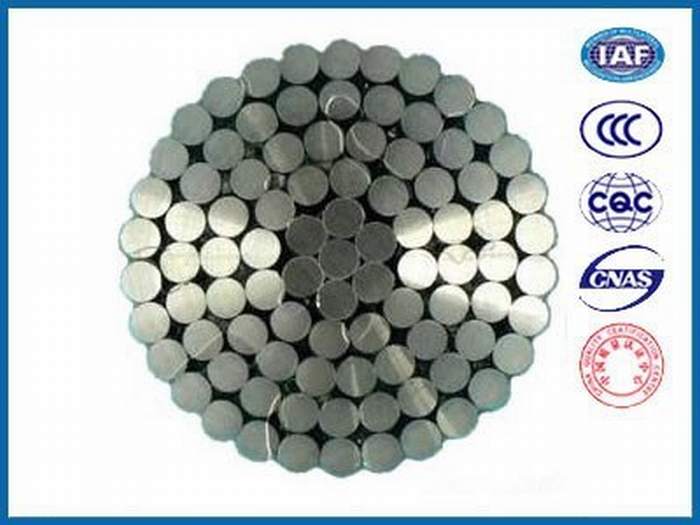

2. ACSR (Aluminum conductor steel reinforced)

(1),Brief Description

ACSR conductor consists of a solid or stranded steel core surrounded by strands of aluminium (E.C.GRADE).

(2),Application

Widely used in power transmission lines with various voltage levels, because they have such good characteristics as simple structure, convenient installation and maintenance, low cost large transmission capacity. And they are also suitable for laying across rivers valleys and the places where special geographical features exist.

3.ACAR Conductor,Aluminum Conductor Aluminium Alloy Reinforced.

(ACAR) is an excellent conductor choice where current carrying capacity,higher strength and a lower conductor weight are critical to the line design.

4.AAAC, All Aluminum Alloy Conductor

(1). Standard: BS EN 50183, ASTM B399, DIN 48201

(2). Specification: AAAC are composed by bare concentric-lay-stranded aluminium alloy wires.

(3). Application: Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum alloy to achieve a high strength-to-weight ratio; affords better sag characteristics. Aluminum alloy gives AAAC higher resistance to corrosion than ACSR.

5.ACSS,( Overhead Aluminium Conductor Steel Supported).

(1), Construction

a non-homogenous conductor, is a concentric-lay stranded conductor made from round aluminum 1350-O wires and round, coated steel core wire(s). Steel wires are coated with Class A coating of zinc – 5% aluminum mischmetal alloy. Other Classes of coatings are also available for additional protection from corrosion. Standard, High, Extra and Ultra High Strength steel are also available.

(2),Features

ACSS conductors are preferred over ACSR conductors for specific transmission line applications:

With zinc – 5% aluminum mischmetal alloy coating on steel wires, ACSS conductors can be operated up to 250 °C.

ACSS conductors carry more current than ACSR conductors due to:Minimum average conductivity of 63% IACS for 1350-O aluminum wires vs. an average conductivity of 61.2% for 1350-H19 aluminum wires in ACSR.

ACSS conductors can be operated up to 250 °C vs. the maximum operating temperature for an ACSR conductor does not exceed 100 °C.

ACSS conductors are prone to resist the effects of aeolian vibration due to very little or no mechanical load on the annealed aluminum wires.

Long term creep is not a factor when designing with ACSS conductors.

6. GSW(Galvanized Steel Wire) ; Guy Wire,Stay Wire

(1) Technical Data

Hot-Dipped Galvanized steel wire

Diameter:1.24~5.50mm

Zinc Coating:150-400g/m2 ASTM class A. class B.

Tensile Strength:900-1720 mpa.

Intensity Level:General,High,Very High.

Min.No. of 360° twists:10~16.

Construction:1×3,1×7,1×19.1×37.

(2) Application

Used as overhead ground wire or static wire on transmission lines, as pole or structure guy wires, and as messenger cable, fields and pastures division, animal containment.

7. ABC Cable (Aerial Bundled Cable) has characters of power-transmitting and strong mechanical. In comparison with bare wire, aerial bundled cable (ABC cable) boasts many advantages, such as:small span in laying, higher safe reliability, better atmosphere aging resistence property. Aerial bundled cable has the priority to be used in urban and rural power-transmitting construction project.

Insulation: PVC or XLPE

ABC Cable Technical characteristics (Duplex Service Drop

| Code Word |

Phase Conductors | Bare Natural | Nominal Weight | Ampacity | Standard Package | |||||||

| Size & Number of wires |

Insulation Thickness |

Nominal Diameter | Size & Number of Wires |

Rated Strength |

kg / km | Coils | Reels | |||||

| Bare | OD | XLPE | Aluminum | Total | ||||||||

| mm | mm | mm | kg | A | m | m | ||||||

| AAC | ||||||||||||

| Pekingese | 6-Solid | 1.14 | 4.1 | 6.4 | 6-7 | 255 | 20.8 | 72.9 | 94 | 78 | 305 | 1000 |

| Collie | 6-7 | 1.14 | 4.6 | 6.9 | 6-7 | 255 | 23.8 | 72.9 | 97 | 78 | 305 | 1000 |

| Cocker | 6-7 | 1.52 | 4.6 | 7.7 | 6-7 | 255 | 32.7 | 72.9 | 106 | 78 | 305 | 1000 |

| Dachshund | 4-Solid | 1.14 | 5.2 | 7.5 | 6-7 | 400 | 26.8 | 114.6 | 141 | 103 | 305 | 500 |

| Spaniel | 4-7 | 1.14 | 5.9 | 8.2 | 6-7 | 400 | 29.8 | 116.1 | 146 | 103 | 305 | 500 |

| Cairn | 4-7 | 1.52 | 5.9 | 8.9 | 6-7 | 400 | 40.2 | 116.1 | 156 | 103 | 305 | 500 |

| Doberman | 2-7 | 1.14 | 7.4 | 9.7 | 2-7 | 612 | 38.7 | 184.5 | 223 | 136 | 152 | 500 |

| Airedale | 1-19 | 1.52 | 8.4 | 11.5 | 1-7 | — | 56.5 | 233.6 | 290 | 158 | 152 | 500 |

| Basset | 1/0-7 | 1.52 | 9.3 | 12.4 | 1/0-7 | 903 | 64.0 | 294.7 | 359 | 182 | 152 | 457 |

| Malemure | 1/0-19 | 1.52 | 9.4 | 12.5 | 1/0-7 | 903 | 64.0 | 294.7 | 359 | 182 | 152 | 457 |

| AAAC | ||||||||||||

| Chihuahua | 6-Solid | 1.14 | 4.1 | 6.4 | 6-7 | 499 | 20.8 | 72.9 | 94 | 78 | 305 | 1000 |

| Vizsla | 6-7 | 1.14 | 4.6 | 6.9 | 6-7 | 499 | 23.8 | 72.9 | 97 | 78 | 305 | 1000 |

| Harrier | 4-Solid | 1.14 | 5.2 | 7.5 | 4-7 | 798 | 26.8 | 116.1 | 143 | 103 | 305 | 500 |

| Whippet | 4-7 | 1.14 | 5.9 | 8.2 | 4-7 | 798 | 29.8 | 116.1 | 146 | 103 | 305 | 500 |

| Schnauzer | 2-7 | 1.14 | 7.4 | 9.7 | 2-7 | 1,270 | 38.7 | 184.5 | 223 | 136 | 152 | 500 |

| Afghan | 1/0-7 | 1.52 | 9.3 | 12.4 | 1/0-7 | 2,023 | 64.0 | 296.1 | 360 | 182 | 152 | 457 |

| heeler | 1/0-19 | 1.52 | 9.4 | 12.5 | 1/0-7 | 2,023 | 64.0 | 296.1 | 360 | 182 | 152 | 457 |

| ACSR | ||||||||||||

| Setter | 6-Solid | 1.14 | 4.1 | 6.4 | 6/6/01 | 540 | 20.8 | 72.9 | 94 | 78 | 305 | 1000 |

| Shepherd | 6-7 | 1.14 | 4.6 | 6.9 | 6/6/01 | 540 | 23.8 | 72.9 | 97 | 78 | 305 | 1000 |

| Retriever | 6-7 | 1.52 | 4.6 | 7.7 | 6/6/01 | 540 | 32.7 | 72.9 | 106 | 78 | 305 | 1000 |

| Eskimo | 4-Solid | 1.14 | 5.2 | 7.5 | 4/6/01 | 844 | 26.8 | 114.6 | 141 | 103 | 305 | 500 |

| Terrier | 4-7 | 1.14 | 5.9 | 8.2 | 4/6/01 | 844 | 29.8 | 116.1 | 146 | 103 | 305 | 500 |

| Yorkshire | 4-7 | 1.52 | 5.9 | 8.9 | 4/6/01 | 844 | 40.2 | 116.1 | 156 | 103 | 305 | 500 |

| Chow | 2-7 | 1.14 | 7.4 | 9.7 | 2/6/01 | 1,293 | 38.7 | 184.5 | 223 | 136 | 152 | 500 |

| Labrador | 1-19 | 1.52 | 8.4 | 11.5 | 1/6/01 | 1,610 | 56.5 | 233.6 | 290 | 158 | 152 | 500 |

| Bloodhound | 1/0-7 | 1.52 | 9.3 | 12.4 | 1/0-6/1 | 1,987 | 64.0 | 294.7 | 359 | 182 | 152 | 457 |

| Bull | 1/0-19 | 1.52 | 9.4 | 12.5 | 1/0-6/1 | 1,987 | 64.0 | 294.7 | 359 | 182 | 152 | 457 |

8.Power cable

(1) 0.6/1kv PVC Cable

(2) 0.6/1kv XLPE Cable

(3) 1.9/3.3kv XLPE Cable

(4) 3.6/6kv XLPE Cable

(5) 3.8/6.6kv XLPE Cable

(6) 6/10kv XLPE Cable

(7) 6.35/11kv XLPE Cable

(8) 8.7/15kv XLPE Cable

(9) 12/20kv XLPE Cable

(10) 12.7/22kv XLPE Cable

(11) 18/30kv XLPE Cable

(12) 19/33kv XLPE Cable

(13) 21/35kv XLPE Cable

(14) 26/35kv XLPE Cable

9.Huatong Cable Inc.

1,More than 30 years experience.

2,100,000m² factory,200 staffs,annual output 100,000 metic tons.

3,Sound Quality Control

(1) Material inspection;

(2) manufacturing inspection;

(3) Finished products inspection;

(4) Inspection before delivery.

(5) Third party inspection.

(6) Inspection of storage at port of departure.

4,ISO Certificated.

5,Plenty of material and lobor gurantee the delivery prompt and price competitive.

6,24/7 service.

10. IEC61089 Standard AAAC

| Code Number | A2 Conductor | A3 Conductor | Max.D.C. Resistance of Conductor at 20°C | ||||||||

| Number of Wires | Diameter of Wires | Diameter of Conductor | Approx. Weight | Rated Strength | Number of Wires | Diameter of Wires | Diameter of Conductor | Approx. Weight | Rated Strength | ||

| mm² | – | mm | mm | kg/km | daN | – | mm | mm | kg/km | daN | Ω/km |

| 16 | 7 | 1.83 | 5.49 | 50.4 | 5.43 | 50.8 | 6.04 | 50.8 | 6.04 | 1.7896 | |

| 25 | 7 | 2.29 | 6.87 | 78.7 | 8.49 | 1.1453 | 79.5 | 9.44 | 79.5 | 9.44 | 1.1453 |

| 40 | 7 | 2.89 | 8.67 | 125.9 | 13.58 | 0.7158 | 127.1 | 15.1 | 127.1 | 15.1 | 0.7158 |

| 63 | 7 | 3.63 | 10.8 | 198.3 | 21.39 | 0.4545 | 200.2 | 23.06 | 200.2 | 23.06 | 0.4545 |

| 100 | 19 | 2.78 | 13.9 | 316.3 | 33.95 | 0.2877 | 319.3 | 37.76 | 319.3 | 37.76 | 0.2877 |

| 125 | 19 | 3.10 | 15.5 | 395.4 | 42.44 | 0.2302 | 399.2 | 47.20 | 399.2 | 47.20 | 0.2302 |

| 160 | 19 | 3.51 | 17.55 | 506.1 | 54.32 | 0.1798 | 511.0 | 58.56 | 511.0 | 58.56 | 0.1798 |

| 200 | 19 | 3.93 | 19.65 | 623.7 | 67.91 | 0.1439 | 638.7 | 73.20 | 638.7 | 73.20 | 0.1439 |

| 250 | 19 | 4.39 | 21.95 | 790.8 | 84.68 | 0.1151 | 798.4 | 91.50 | 798.4 | 91.50 | 0.1151 |

| 315 | 37 | 3.53 | 24.71 | 998.9 | 106.95 | 0.0916 | 1008.4 | 115.29 | 1008.4 | 115.29 | 0.0916 |

| 400 | 37 | 3.98 | 27.86 | 1268.4 | 135.81 | 0.0721 | 1280.5 | 146.4o | 1280.5 | 146.4o | 0.0721 |

| 450 | 37 | 4.22 | 29.54 | 1426.9 | 152.79 | 0.0641 | 1440.5 | 164.70 | 1440.5 | 164.70 | 0.0641 |

| 500 | 37 | 4.45 | 31.15 | 1585.5 | 169.76 | 0.0577 | 1600.6 | 183.oo | 1600.6 | 183.oo | 0.0577 |

| 560 | 61 | 3.67 | 33.03 | 1778.4 | 190.14 | 0.0516 | 1795.3 | 204.95 | 1795.3 | 204.95 | 0.0516 |

| 630 | 61 | 3.89 | 35.01 | 2000.7 | 213.90 | 0.0458 | 2019.8 | 230.58 | 2019.8 | 230.58 | 0.0458 |

| 710 | 61 | 4.13 | 37.17 | 2254.8 | 241.07 | 0.0407 | 2276.2 | 259.86 | 2276.2 | 259.86 | 0.0407 |

| 800 | 61 | 4.38 | 39.42 | 2540.6 | 271.62 | 0.0361 | 2564.8 | 282.80 | 2564.8 | 282.80 | 0.0361 |

| 900 | 91 | 3.81 | 41.91 | 2861.1 | 305.58 | 0.0632 | 2888.3 | 329.40 | 2888.3 | 329.40 | 0.0321 |

| 1000 | 91 | 4.01 | 44.11 | 3179.0 | 339.53 | 0.0289 | 3209.3 | 366.00 | 3209.3 | 366.00 | 0.0289 |

| 1120 | 91 | 4.25 | 46.75 | 3560.5 | 380.27 | 0.0258 | 3594.4 | 409.92 | 3594.4 | 409.92 | 0 0258 |

| 1250 | 91 | 4.49 | 49.39 | 3973.7 | 424.41 | 0 0231 | – | – | – | – | |

- Next: Galvanized Steel Wire (GSW) 7/14 7/12 7/10

- Previous: Acar (Aluminum Conductor Alloy Reinforced) for Overhead Use ASTM B524