Primary Ud Cable, 25 Kv, Al/Epr/Neutral/LLDPE (AEIC CS 8/ICEA S-94-649)

Product Detail

Basic Info

Extra Informatie.

Beschrijving

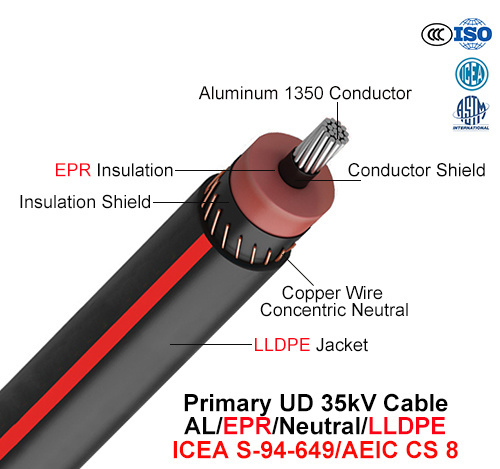

Primary UD Cable, 25kv Al/100% Epr/Full Neutral (AEIC CS 8/ICEA S-94-649)

Applications:

Predominantly used for primary underground distribution; Suitable for use in wet or dry locations, direct burial, underground duct, and where exposed to sunlight. To be used at 15, 000 volts or less and at conductor temperatures not to exceed 90° C for normal operation.

Specifications:

Primary UD Cable meets or exceeds the following ASTM specifications:

B-3 Soft Annealed Copper Wire.

B-8 Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard or Soft.

B-230 Aluminum, 1350-H19 Wire for Electrical Purposes.

B-231 Aluminum 1350 Conductors, Concentric-Lay-Stranded.

B-609 Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes.

Primary UD Cable is manufactured to the latest edition of the following specifications, and in case of specification conflicts, in the order listed:

ANSI/ICEA S-94-649

AEIC CS-8

RUS U-1

Construction:

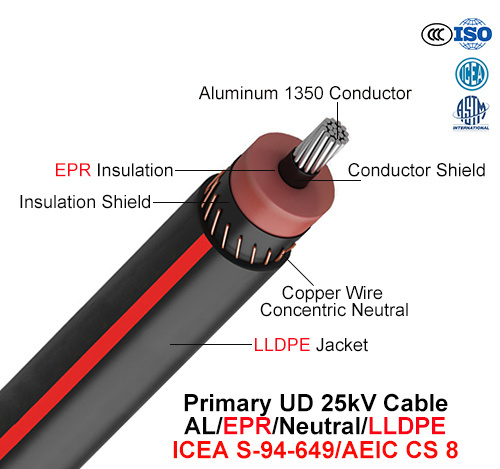

The phase conductor is concentrically stranded, compressed soft copper or 1350-H16/26 aluminum alloy. The cable is composed of the conductor with moisture block in the strands, covered by a semi-conducting cross-linked polyethylene strand shield, an ethylene propylene rubber primary insulation, and a semi-conducting cross-linked polyethylene insulation shield. Conductors are available with either 100% or 133% insulation levels. A concentric neutral of bare copper wires and an insulating polyethylene jacket is applied over the insulation shield. The cable is identified by surface print on the jacket and with the lightning bolt symbol for supply cables indented in the jacket. A semi-conducting polyethylene jacket is available upon request.

Maximum Conductor Normal Operation: – 90O C;

Emergency Overload: – 130O C

Temperatures: Short Circuit – 250 C

Application: Medium voltage power cable for single phase underground distribution (UD), including getaway systems in low profile substations. Application:

Features: 1. Simultaneous extrusion of strand shield, insulation, and insulation shield (triple extrusion, dry curing process) forms a virtually perfect cable core, eliminating unequal electrical stress.

2. Ethylene Propylene Rubber (EPR) insulation offers: Excellent heat, moisture and corona resistance; Electrical stability under stress; Low dielectric loss, chemical resistance.

| 1/3 Neutral | Full Neutral | ||||||||||||||

| Size AWG or kcmil | Number of Strands | Nominal OD Over Insulation in | Number of Wires | Size AWG | Jacket Thickness mil | Approximate Outside Diameter in | Approximate Net Weight lb/kft | Size AWG or kcmil | Number of Strands | Nominal OD Over Insulation in | Number of Wires | Size AWG | Jacket Thickness mil | Approximate Outside Diameter in | Approximate Net Weight lb/kft |

| Aluminum 100% Insulation Level (260 mil) | |||||||||||||||

| 1 | 19 | 0.88 | 6 | 14 | 50 | 1.19 | 644 | 1 | 19 | 0.88 | 13 | 14 | 50 | 1.19 | 728 |

| 1/0 | 1 | 0.89 | 6 | 14 | 50 | 1.19 | 661 | 1/0 | 1 | 0.89 | 16 | 14 | 50 | 1.19 | 781 |

| 1/0 | 19 | 0.92 | 6 | 14 | 50 | 1.23 | 692 | 1/0 | 19 | 0.92 | 16 | 14 | 50 | 1.23 | 812 |

| 2/0 | 19 | 0.97 | 7 | 14 | 50 | 1.27 | 760 | 2/0 | 19 | 0.97 | 20 | 14 | 50 | 1.27 | 917 |

| 3/0 | 19 | 1.02 | 9 | 14 | 50 | 1.34 | 875 | 2/0 | 19 | 0.97 | 13 | 12 | 50 | 1.30 | 952 |

| 4/0 | 19 | 1.07 | 11 | 14 | 50 | 1.40 | 981 | 3/0 | 19 | 1.02 | 25 | 14 | 50 | 1.34 | 1068 |

| 250 | 37 | 1.13 | 13 | 14 | 50 | 1.46 | 1080 | 3/0 | 19 | 1.02 | 16 | 12 | 50 | 1.38 | 1102 |

| 350 | 37 | 1.23 | 18 | 14 | 50 | 1.56 | 1307 | 4/0 | 19 | 1.07 | 32 | 14 | 50 | 1.40 | 1234 |

| 500 | 37 | 1.36 | 25 | 14 | 80 | 1.75 | 1692 | 4/0 | 19 | 1.07 | 20 | 12 | 50 | 1.43 | 1261 |

| 500 | 37 | 1.36 | 16 | 12 | 80 | 1.78 | 1735 | 4/0 | 19 | 1.07 | 13 | 10 | 50 | 1.48 | 1313 |

| 750 | 61 | 1.57 | 24 | 12 | 80 | 2.02 | 2340 | 250 | 37 | 1.13 | 25 | 12 | 50 | 1.49 | 1433 |

| 750 | 61 | 1.57 | 15 | 10 | 80 | 2.06 | 2392 | 250 | 37 | 1.13 | 16 | 10 | 50 | 1.53 | 1482 |

| 1000 | 61 | 1.72 | 31 | 12 | 80 | 2.17 | 2829 | 350 | 37 | 1.23 | 32 | 12 | 50 | 1.59 | 1736 |

| 1000 | 61 | 1.72 | 20 | 10 | 80 | 2.21 | 2903 | 350 | 37 | 1.23 | 20 | 10 | 80 | 1.70 | 1843 |

| 1000 | 61 | 1.72 | 16 | 9 | 80 | 2.24 | 2944 | 350 | 37 | 1.23 | 16 | 9 | 80 | 1.72 | 1875 |

| – | – | – | – | – | – | – | – | 500 | 37 | 1.36 | 29 | 10 | 80 | 1.83 | 2361 |

| – | – | – | – | – | – | – | – | 750 | 61 | 1.57 | 28 | 8 | 80 | 2.12 | 3362 |

| – | – | – | – | – | – | – | – | 1000 | 61 | 1.72 | 37 | 8 | 80 | 2.27 | 4163 |

| Aluminum 133% Insulation Level (320 mil) | |||||||||||||||

| 1/0 | 19 | 1.05 | 6 | 14 | 50 | 1.37 | 839 | 1/0 | 19 | 1.05 | 16 | 14 | 50 | 1.37 | 959 |

| 2/0 | 19 | 1.09 | 7 | 14 | 50 | 1.42 | 913 | 2/0 | 19 | 1.09 | 20 | 14 | 50 | 1.42 | 1070 |

| 3/0 | 19 | 1.14 | 9 | 14 | 50 | 1.47 | 1010 | 2/0 | 19 | 1.09 | 13 | 12 | 50 | 1.45 | 1108 |

| 4/0 | 19 | 1.20 | 11 | 14 | 50 | 1.52 | 1122 | 3/0 | 19 | 1.14 | 25 | 14 | 50 | 1.47 | 1203 |

| 250 | 37 | 1.25 | 13 | 14 | 50 | 1.58 | 1226 | 3/0 | 19 | 1.14 | 16 | 12 | 50 | 1.50 | 1239 |

| 350 | 37 | 1.35 | 18 | 14 | 80 | 1.74 | 1533 | 4/0 | 19 | 1.20 | 32 | 14 | 50 | 1.52 | 1375 |

| 500 | 37 | 1.48 | 25 | 14 | 80 | 1.87 | 1867 | 4/0 | 19 | 1.20 | 20 | 12 | 50 | 1.55 | 1405 |

| 500 | 37 | 1.48 | 16 | 12 | 80 | 1.91 | 1912 | 4/0 | 19 | 1.20 | 13 | 10 | 50 | 1.60 | 1460 |

| 750 | 61 | 1.69 | 24 | 12 | 80 | 2.14 | 2540 | 250 | 37 | 1.25 | 25 | 12 | 50 | 1.61 | 1583 |

| 750 | 61 | 1.69 | 15 | 10 | 80 | 2.18 | 2596 | 250 | 37 | 1.25 | 16 | 10 | 80 | 1.72 | 1703 |

| 1000 | 61 | 1.84 | 31 | 12 | 80 | 2.29 | 3045 | 350 | 37 | 1.35 | 32 | 12 | 80 | 1.78 | 1966 |

| 1000 | 61 | 1.84 | 20 | 10 | 80 | 2.33 | 3123 | 350 | 37 | 1.35 | 20 | 10 | 80 | 1.82 | 2011 |

| 1000 | 61 | 1.84 | 16 | 9 | 80 | 2.36 | 3165 | 350 | 37 | 1.35 | 16 | 9 | 80 | 1.84 | 2045 |

| – | – | – | – | – | – | – | – | 500 | 37 | 1.48 | 29 | 10 | 80 | 1.95 | 2541 |

- Next: Liycy (B) Tp Data Cable, 300/500 V, Flexible Cu/PVC/Petp/Tcwb/PVC (DIN VDE 0812)

- Previous: Primary Ud Cable, 35 Kv, Cu/Epr/Neutral/LLDPE (AEIC CS 8/ICEA S-94-649)