Aluminium Conductor, Aluminium Clad Steel Reinforced, ACSR voor overhead, ACSR voor telecommunicatie

Basic Info

CE ,

CCC ,

RoHS ,

VDE

Extra Informatie.

Beschrijving

1. Applications

ACSR have been widely used in power transmission lines with various voltage levels, because they have such good characteristics as simple structure, convenient installation and maintenance, low cost large transmission capacity. And they are also suitable for laying across rivers valleys and the places where special geographical features exist.

2. Service Performance

(1). The permissible long-time operating temperature for aerial conductor is 70ºC.

(2). Under the circumstance that rare climate is occuring and ice coverage rate low in heavy ice area, the biggest stress of cable at the lowest point of the sag should not exceed 60% of the short-time destructive power.

(3). When connecting conductors, the conductor beside the connecting tube cant be prominent. Otherwise, the force on the operating conductors will be unbalanced. After connectors are install, the connecting tube should be painted by moisture-proof varnish in order to protect it from corrosion.

(4). Under installaion, the arc downing stress of all the conductors should be the same. With in the permissible distance of crossing buildings or dropping to the ground, the stress can be 10-15% higher than regular stress.

3. Product Performance

(1). The electrical performance of AAC and ACSR is indicated in DCΩ /km(20ºC). The resistivity of the hard aluminum wire for stranded wires is not greater than 28.264 nΩ . M of international standard value.

(2). The rated tensile strength of AAC is denoted with the result of total cross-section of all aluminum conductors multiplied by min. Tensile of corresponding size specified in the standard for aluminum wire.

(3). The rated tensile strengh of ACSR is denoted with sum of all aluminum conductorstensile strength and steels tensile strength.

A. The tensile strength of all aluminum conductors is denoted with the result of all cross-sections of aluminum conductors multiplied by min. Tensile strength of corresponding size specified in the standard for aluminum wire.

B. The tensile strength of all steel wire is denoted with the result of all cross-sections of steel wires multiplied by the stress at 1% elongation of corresponding size specified in the standard for steel wire.

We can also produce the wire according to customer’s requirement

Our Advantages:

1.Short delivery and timely delivery

2.considerate after-sales service

3.Professional manufacture for ACSR with more than 20 years experience

4.Full set of testing equipment to ensure products’ performance

5.Strict quality control process

6.We are factory and our price is competitive

| Code name |

structure | mm2 Calculated Area |

Dia mm |

ACSR/AW | Min Tensile Strength |

|||||||

| Size | Al | As | Al | As | ASCR/AW | () AS |

||||||

| kg/km | kN | |||||||||||

| Thrasher | 2312000 | 76/4.43 | 19/2.07 | 1172 | 63.94 | 45.79 | 10.35 | 3679 | 246 | |||

| Kiwi | 2167000 | 72/4.41 | 7/2.94 | 1098 | 47.52 | 44.10 | 8.82 | 3366 | 218 | |||

| Bluebird | 2156000 | 84/4.07 | 19/2.44 | 1092 | 88.84 | 44.76 | 12.20 | 3627 | 262 | |||

| Chukar | 1780000 | 84/3.70 | 19/2.22 | 902 | 73.54 | 40.70 | 11.10 | 2996 | 220 | |||

| Falcon | 1590000 | 54/4.36 | 19/2.62 | 806 | 102.43 | 39.26 | 13.10 | 2917 | 236 | |||

| Lapwing | 1590000 | 45/4.78 | 7/3.18 | 806 | 55.60 | 38.19 | 9.54 | 2598 | 186 | |||

| Parrot | 1510500 | 54/4.25 | 19/2.55 | 765 | 97.03 | 38.22 | 12.75 | 2768 | 224 | |||

| Nuthatch | 1510500 | 45/4.65 | 7/3.10 | 765 | 52.83 | 37.21 | 9.30 | 2467 | 177 | |||

| Plover | 1431000 | 54/4.14 | 19/2.48 | 725 | 91.78 | 37.24 | 12.40 | 2625 | 212 | |||

| Drake | 795000 | 26/4.44 | 7/3.45 | 403 | 65.44 | 28.15 | 10.35 | 1549 | 136 | |||

| Cuckoo | 795000 | 24/4.62 | 7/3.08 | 403 | 52.15 | 27.72 | 9.24 | 1460 | 122 | |||

| Redwing | 715500 | 30/3.92 | 19/2.35 | 363 | 82.41 | 27.43 | 11.75 | 1552 | 149 | |||

| Starling | 715500 | 26/4.21 | 7/3.28 | 363 | 59.15 | 26.68 | 9.84 | 1393 | 122 | |||

| Stilt | 715500 | 24/4.39 | 7/2.92 | 363 | 46.88 | 26.32 | 8.76 | 1314 | 110 | |||

| Gannet | 666600 | 26/4.07 | 7/3.16 | 338 | 54.90 | 25.76 | 9.48 | 1298 | 116 | |||

| Flamingo | 666600 | 24/4.23 | 7/2.82 | 338 | 43.72 | 25.38 | 8.46 | 1225 | 103 | |||

| Swift | 636000 | 36/3.78 | 1/3.38 | 322 | 8.97 | 23.66 | 3.38 | 946 | 61 | |||

| Egret | 636000 | 30/3.70 | 19/2.22 | 322 | 73.54 | 25.89 | 11.10 | 1381 | 133 | |||

| Sooter | 636000 | 30/3.70 | 7/3.70 | 322 | 75.26 | 25.90 | 11.10 | 1391 | 130 | |||

| Grosbeak | 636000 | 26/3.97 | 7/3.09 | 322 | 52.49 | 25.15 | 9.27 | 1238 | 110 | |||

| Rook | 636000 | 24/4.14 | 7/2.76 | 322 | 41.88 | 24.84 | 8.28 | 1168 | 98 | |||

| Kingbird | 636000 | 18/4.78 | 1/4.78 | 322 | 17.95 | 23.90 | 4.78 | 1006 | 67 | |||

| Teal | 605000 | 30/3.61 | 19/2.16 | 307 | 69.62 | 25.24 | 10.80 | 1314 | 127 | |||

| Woodduck | 605000 | 30/3.61 | 7/3.61 | 307 | 71.65 | 25.27 | 10.83 | 1323 | 126 | |||

| Squab | 605000 | 26/3.87 | 7/3.01 | 307 | 49.81 | 24.51 | 9.03 | 1177 | 105 | |||

| Peacock | 605000 | 24/4.03 | 7/2.69 | 307 | 39.78 | 24.19 | 8.07 | 1112 | 93 | |||

| Eagle | 556500 | 30/3.46 | 7/3.46 | 282 | 65.82 | 24.22 | 10.38 | 1217 | 119 | |||

| Dove | 556500 | 26/3.72 | 7/2.89 | 282 | 45.92 | 23.55 | 8.67 | 1083 | 97 | |||

| Parakeet | 556500 | 24/3.87 | 7/2.58 | 282 | 36.60 | 23.22 | 7.74 | 1022 | 86 | |||

| Ospray | 556500 | 18/4.47 | 1/4.47 | 282 | 15.69 | 22.35 | 4.47 | 880 | 59 | |||

| Hen | 477000 | 30/3.20 | 7/3.20 | 242 | 56.30 | 22.40 | 9.60 | 1043 | 104 | |||

| Hawk | 477000 | 26/3.44 | 7/2.68 | 242 | 34.49 | 21.80 | 8.04 | 929 | 84 | |||

| Ficker | 477000 | 24/3.58 | 7/2.39 | 242 | 31.40 | 21.49 | 7.17 | 877 | 74 | |||

| Pelican | 477000 | 18/4.14 | 1/4.14 | 242 | 13.46 | 20.70 | 4.14 | 755 | 51 | |||

| Lark | 397500 | 30/2.92 | 7/2.92 | 201 | 46.88 | 20.44 | 8.76 | 869 | 87 | |||

| Lbis | 397500 | 26/3.14 | 7/2.44 | 201 | 32.73 | 19.88 | 7.32 | 774 | 70 | |||

| Brant | 397500 | 24/3.27 | 7/2.18 | 201 | 26.13 | 19.62 | 6.54 | 731 | 63 | |||

| Chickadee | 397500 | 18/3.77 | 1/3.77 | 201 | 11.16 | 18.85 | 3.77 | 628 | 44 | |||

| Oriole | 336400 | 30/2.69 | 7/2.69 | 170 | 39.78 | 18.83 | 8.07 | 737 | 74 | |||

| Linnet | 336400 | 26/2.89 | 7/2.25 | 170 | 27.83 | 18.31 | 6.75 | 655 | 60 | |||

| Merlin | 336300 | 18/3.47 | 1/3.47 | 170 | 9.46 | 17.35 | 3.47 | 531 | 38 | |||

| Ostrich | 300000 | 26/2.73 | 7/2.12 | 152 | 24.71 | 17.28 | 6.36 | 583 | 54 | |||

| Partridge | 266800 | 26/2.57 | 7/2.00 | 135 | 21.99 | 16.28 | 6.00 | 519 | 48 | |||

| Waxwing | 266800 | 18/3.09 | 1/3.09 | 135 | 7.50 | 15.45 | 3.09 | 421 | 30 | |||

| Dorking | 190800 | 12/3.20 | 7/3.20 | 96.7 | 56.30 | 16.00 | 9.60 | 641 | 81 | |||

| Dotterel | 176900 | 12/3.08 | 7/3.08 | 89.6 | 52.15 | 15.40 | 9.24 | 594 | 75 | |||

| Guinea | 159000 | 12/2.92 | 7/2.92 | 80.6 | 46.88 | 14.60 | 8.76 | 534 | 68 | |||

| Leghom | 134600 | 12/2.69 | 7/2.69 | 68.2 | 39.78 | 13.45 | 8.07 | 452 | 58 | |||

| Minorca | 110800 | 12/2.44 | 7/2.44 | 56.1 | 32.73 | 12.20 | 7.32 | 372 | 48 | |||

| Patrel | 101800 | 12/2.34 | 7/2.34 | 51.6 | 30.10 | 11.70 | 7.02 | 342 | 44 | |||

| Grouse | 80000 | 8/2.54 | 1/4.24 | 40.5 | 14.11 | 9.32 | 4.24 | 205 | 22 | |||

| Penguin | (4/0) | 6/4.77 | 1/4.77 | 107 | 17.87 | 14.31 | 4.77 | 412 | 34 | |||

| Pigeon | (3/0) | 6/4.25 | 1/4.25 | 85.03 | 14.19 | 12.75 | 4.25 | 326 | 28 | |||

| Quail | (2/0) | 6/3.78 | 1/3.78 | 67.44 | 11.22 | 11.34 | 3.78 | 259 | ||||

ACSR/AW-Aluminum Conductor Aluminum Clad Steel Reinforced

Standard

IEC61089, BS215 part2, ASTM B232, DIN48204, BS EN50182.

ACSR/AW bare conductor meets or exceeds the following ASTM specifications:

• B230 Aluminum 1350-H19 Wire for Electrical Purposes.

• B502 Aluminum-Clad Steel Core Wire for Use in Overhead Electrical Aluminum Conductors.

• B549 Concentric-Lay Stranded Aluminum Conductors, Aluminum-Clad Steel Reinforced (ACSR-AW)

APPLICATIONS

Used as bare overhead transmission and as primary and secondary distribution cable.

It has good characteristics such as simple structure, convenient installation and maintenance, low cost for the line, large transmission capacity. It is also suitable for laying across rivers and valleys where special geographical features exist.

ACSR/AW offers strength characteristics similar to ACSR, along with slightly greater ampacity and resistance to corrosion due to aluminum-cladding of the steel core wires.

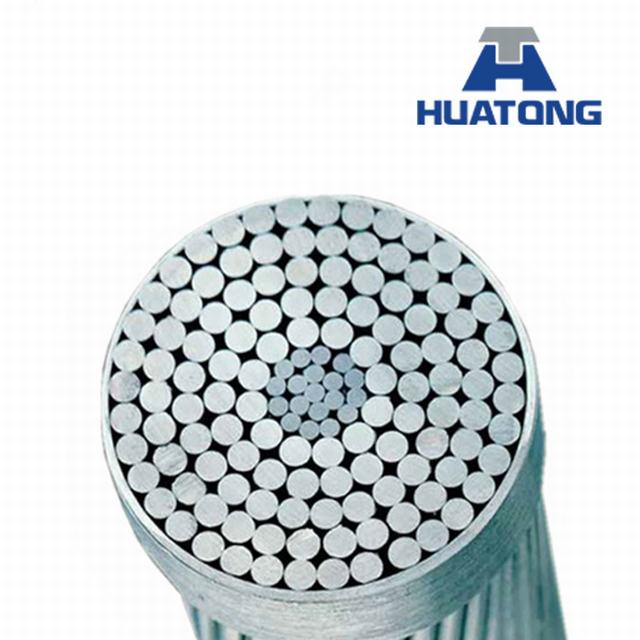

CONSTRUCTION

Aluminum 1350-H19 wires, concentrically stranded around aluminum-clad steel core.

IEC1089

| Code number | Steel ratio (%) |

Cross section (mm²) |

Stranding & wire diam. (Nºx mm) |

Overall diam (mm) |

Unit weight (kg/km) |

Rated strength (KN) |

Electr. resist. at 20ºC (Ω/km) |

|||

| Al | SA1A | Total | ||||||||

| Al | SA1A | |||||||||

| 16 | 16.7 | 15 | 2.56 | 17.6 | 6×1.81 | 1×1.81 | 5.43 | 59.0 | 5.91 | 1.7923 |

| 25 | 16.7 | 24 | 4.00 | 28.0 | 6×2.26 | 1×2.26 | 6.78 | 92.1 | 9.00 | 1.1471 |

| 40 | 16.7 | 38 | 6.40 | 44.4 | 6×2.85 | 1×2.85 | 8.55 | 147.4 | 14.21 | 0.7169 |

| 63 | 16.7 | 60 | 10.08 | 70.1 | 6×3.58 | 1×3.58 | 10.70 | 232.2 | 21.17 | 0.4552 |

| 100 | 16.7 | 96 | 16.00 | 112.0 | 6×4.51 | 1×4.51 | 13.50 | 368.6 | 31.84 | 0.2868 |

| 125 | 5.6 | 123 | 6.85 | 130.0 | 18×2.95 | 1×2.95 | 14.80 | 384.3 | 29.18 | 0.2304 |

| 125 | 16.3 | 120 | 19.60 | 140.0 | 26×2.43 | 7×1.89 | 15.40 | 460.8 | 44.49 | 0.2308 |

| 160 | 5.6 | 158 | 8.77 | 167.0 | 18×3.34 | 1×3.34 | 16.70 | 491.9 | 36.38 | 0.1800 |

| 160 | 16.3 | 154 | 25.00 | 179.0 | 26×2.74 | 7×2.13 | 17.40 | 589.8 | 56.18 | 0.1803 |

| 200 | 5.6 | 197 | 10.96 | 208.0 | 18×3.74 | 1×3.74 | 18.70 | 614.9 | 43.62 | 0.1440 |

| 200 | 16.3 | 192 | 31.30 | 223.0 | 26×3.07 | 7×2.39 | 19.40 | 737.2 | 69.27 | 0.1443 |

| 250 | 9.8 | 244 | 24.00 | 268.0 | 32×3.76 | 7×2.09 | 21.30 | 830.9 | 67.8 | 0.1153 |

| 250 | 16.3 | 240 | 39.10 | 279.0 | 26×3.43 | 7×2.67 | 21.70 | 921.5 | 86.58 | 0.1154 |

| 315 | 6.9 | 310 | 21.40 | 331.0 | 45×2.96 | 7×1.97 | 23.70 | 996.4 | 78.33 | 0.0917 |

| 315 | 16.3 | 303 | 49.30 | 352.0 | 26×3.75 | 7×2.99 | 24.40 | 1161.1 | 107.58 | 0.0916 |

| 400 | 6.9 | 393 | 27.20 | 420.0 | 45×3.34 | 7×2.22 | 26.70 | 1265.3 | 97.50 | 0.0722 |

| 400 | 13 | 387 | 50.20 | 437.0 | 54×3.02 | 7×3.02 | 27.20 | 1402.9 | 124.20 | 0.0723 |

| 450 | 6.9 | 442 | 40.60 | 483.0 | 45×3.54 | 7×2.36 | 28.30 | 1423.4 | 107.48 | 0.0642 |

| 450 | 13 | 436 | 56.50 | 493.0 | 54×3.21 | 7×3.21 | 28.90 | 1578.2 | 139.72 | 0.0642 |

| 500 | 6.9 | 492 | 34.00 | 526.0 | 45×3.73 | 7×2.49 | 29.80 | 1581.6 | 119.42 | 0.0578 |

| 500 | 13 | 484 | 62.80 | 547.0 | 54×3.78 | 7×3.38 | 30.40 | 1753.6 | 153.99 | 0.0578 |

| 560 | 6.9 | 550 | 38.10 | 588.0 | 45×3.95 | 7×2.63 | 31.60 | 1771.4 | 133.75 | 0.0516 |

| 560 | 12.7 | 543 | 68.80 | 612.0 | 54×3.58 | 19×2.15 | 32.20 | 1956.3 | 169.36 | 0.0516 |

| 630 | 6.9 | 619 | 42.80 | 662.0 | 45×4.19 | 7×2.79 | 33.50 | 1992.8 | 150.47 | 0.0458 |

| 630 | 12.7 | 611 | 77.30 | 688.0 | 54×3.79 | 19×2.28 | 34.20 | 2200.9 | 190.52 | 0.0459 |

| 710 | 6.9 | 698 | 48.30 | 746.0 | 45×4.44 | 7×2.96 | 35.60 | 2245.8 | 169.57 | 0.0407 |

| 710 | 12.7 | 688 | 87.20 | 775.0 | 54×4.03 | 19×2.42 | 36.30 | 2480.3 | 214.72 | 0.0407 |

| 800 | 4.3 | 791 | 34.20 | 825.0 | 72×3.74 | 7×2.49 | 37.40 | 2412.8 | 167.67 | 0.0361 |

| 800 | 8.3 | 784 | 65.30 | 849.0 | 84×3.45 | 7×3.45 | 37.90 | 2598.9 | 206.37 | 0.0362 |

| 800 | 12.7 | 775 | 98.20 | 873.0 | 54×4.28 | 19×2.57 | 38.50 | 2794.7 | 241.94 | 0.0361 |

| 900 | 4.3 | 890 | 38.50 | 929.0 | 72×3.97 | 7×2.65 | 39.70 | 2714.4 | 188.63 | 0.0321 |

| 900 | 8.3 | 882 | 73.50 | 956.0 | 84×3.66 | 7×3.66 | 40.20 | 2923.8 | 224.82 | 0.0321 |

| 1000 | 4.3 | 989 | 42.70 | 1032.0 | 72×4.18 | 7×2.79 | 41.80 | 3016.0 | 209.59 | 0.0289 |

| 1120 | 4.2 | 1108 | 46.80 | 1155.0 | 72×4.43 | 19×1.77 | 44.30 | 3372.6 | 233.48 | 0.0258 |

| 1120 | 8.1 | 1098 | 89.40 | 1187.0 | 84×4.08 | 19×2.45 | 44.90 | 3628.4 | 282.88 | 0.0258 |

| 1250 | 4.2 | 1237 | 52.20 | 1289.0 | 72×4.68 | 19×1.87 | 46.80 | 3764.1 | 260.58 | 0.0231 |

| 1250 | 8.1 | 1225 | 99.80 | 1325.0 | 84×4.31 | 19×2.59 | 47.40 | 4049.5 | 315.72 | 0.0231 |

|

acsr |

Aluminum Conductor Steel Reinfored ACSR as our typical products are have been exported to East South Asia,Middle-east,Africa,South Afirca and USA inculding Indonesia,Malaysia,Jordan, Somalia,Ghana, Malawi,Dubai,USA. |

| Features | a.High tensile strength b.Long life c.Light in weight d.Suitable for high as well as extra high overhead voltage lines |

| Brief Description |

ACSR conductor consists of a solid or stranded steel core surrounded by strands of aluminium (E.C. GRADE). ACSR CONDUCTOR is available in a wide range of steel varying from as low as 6% to as high as 40 %. The higher strength ACSR CONDUCTORS are used for river crossings, overhead ground wires, installations involving extra long spans etc.. Against any given resistance of conductor, ACSR CONDUCTORS may be manufactured for having a wide range of tensile strength as per requirement. The principal advantage of these conductors are high tensile strength and light weight with longer spans as well as with lesser supports. Due to the greater diameter of ACSR CONDUCTORS a much higher corona limit can be obtained causing big advantages on high as well as extra high voltage overhead lines. |

| Applications | Used as bare overhead transmission cable and as primary and secondary distribution cable. ACSR CONDUTOR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing ampacity. ACSR CONDUTORS are used extensively for overhead ground wires, river crossings etc. These ACSR CONDUTORS are available with us in various types for meeting the exact requirements of the clients. |

| Construction | Aluminum1350-H19 wires, concentrically stranded about a steel core. Core wire for ACSR is available with class A, B,or C galvanizing; ""aluminized"" aluminum coated (AZ); or aluminum-clad (AW). Additional corrosion protection is available through the application of grease to the core or infusion of the complete cable with grease. Standard |

| We can produce as per the standard of GB, IEC, ASTM,DIN,CSA,JIS and also particularly customize and manufacture according to your special requirement. | |

- Next: Zhengzhou 35mm2 Sigle Core XLPE Insulation Power Cable

- Previous: 15kv, 30kv 1c500sqmm Power Cable for Nicaragua

Contact us

Soortgelijk of gerelateerd

-

Aluminium Conductor, Versterkt Staal/Acsr Conductor/Bare Conductor

-

Aluminium Conductor, Met Staal Verstevigde Acsr Bare Conductor

-

Aluminium Conductor, Aluminium Clad Steel Versterkt, Acsr Voor Overhead Telecommunication

-

Aluminium Conductor, Aluminium Clad Steel Reinforced, ACSR voor overhead, ACSR voor telecommunicatie